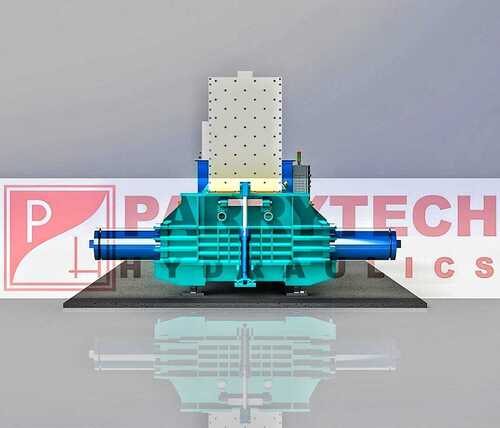

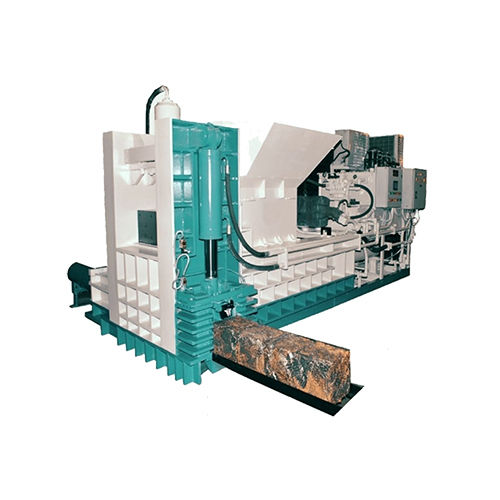

Horizontal Paper Baler

7800000.0 INR/Plant

Product Details:

- Nominal Force 120 ton

- Usage Industrial

- Power Source Hydraulic

- Size 44*42 inch

- Condition New

- Height 20-30 Foot (ft)

- Product Type Bailing Machine

- Click to View more

X

Horizontal Paper Baler Price And Quantity

- 7800000.0 INR/Plant

- 1 Plant

Horizontal Paper Baler Product Specifications

- 6 Foot (ft)

- New

- 120 ton

- 440 Volt (v)

- Industrial

- Dark grey

- automatic

- 23000-24000 Kilograms (kg)

- NA

- provided

- Bailing Machine

- 20-30 Foot (ft)

- Yes

- 38 Foot (ft)

- 44*42 inch

- 440 Volt (v)

- NA

- Hydraulic

- 50HP

Horizontal Paper Baler Trade Information

- 5 Plant Per Month

- 120 Days

Product Description

A paper baling machine, also known as a paper baler, is a machine used to compress and bundle waste paper into manageable and transportable bales. The machine typically uses hydraulic pressure to compress the paper waste and wrap it tightly with wire or strapping material.Paper baling machines are commonly used in recycling facilities, paper mills, printing presses, and other industries where paper waste is generated. The baled paper can be transported to recycling facilities for further processing, where it can be turned into new paper products.

There are different types of paper baling machines available, such as vertical and horizontal balers. Vertical balers are typically used for smaller volumes of paper waste and can be operated manually or with an electric motor. Horizontal balers are designed for larger volumes of waste and are typically used in larger facilities where high volumes of waste are generated.

The benefits of using a paper baling machine include reducing the volume of paper waste, making it easier to transport and handle, and promoting sustainability by diverting paper waste from landfills. Additionally, baling paper waste can also generate revenue for businesses that sell the baled paper to recycling facilities.In summary, a paper baling machine is an essential piece of equipment for managing paper waste in various industries, providing a cost-effective and environmentally friendly solution for handling and transporting paper waste.

Powerful & Reliable Industrial Baling

Engineered for high-capacity industrial recycling, this horizontal paper baler converts large paper and cardboard quantities into manageable bales. Its 120-ton nominal force combined with a massive 50HP hydraulic system delivers top-tier performance essential for modern recycling operations in India. The sturdy construction ensures long-term reliability in any demanding facility.

User-Friendly Automation for Streamlined Workflow

With an advanced PLC automatic system, the baler minimizes manual intervention, increasing operational efficiency and safety. The inclusion of a clear pressure gauge and easy-to-use controls simplifies everyday usage. Its solenoid valve boosts hydraulic performance, making maintenance straightforward even for high-throughput environments.

FAQs of Horizontal Paper Baler:

Q: How does the horizontal paper baler enhance recycling efficiency in industrial settings?

A: The baler automates the compression of paper waste into tightly packed bales, reducing handling and storage space while expediting recycling processes. Its high-pressure hydraulic system and automatic PLC controls make continuous operation both efficient and safe.Q: What types of materials can be processed with this baler?

A: This machine is specifically designed for large-volume paper and cardboard recycling, making it suitable for use in paper mills, warehouses, and industrial recycling plants.Q: When is the best time to perform maintenance on the baler?

A: Routine maintenance should be conducted after every major production cycle or as specified in the user manual. Regular inspections of hydraulic components and the PLC system help prevent downtime and extend equipment life.Q: Where can this baler be installed for optimal performance?

A: The horizontal paper baler requires a spacious, level industrial environment, ideally near the main waste collection and sorting area to optimize workflow and ensure safety.Q: What is the process for operating the automatic PLC system?

A: Operators simply load the paper waste, initiate the sequence through the user interface, and monitor key parameters via the pressure gauge. The PLC system automates the compression and ejection process, streamlining operations.Q: How does the balers nominal force of 120 tons contribute to its operation?

A: The powerful 120-ton force enables the machine to form dense, stable bales rapidly, accommodating large volumes and ensuring efficient material handling for industrial-scale recycling.Q: What are the main benefits of using this particular baler in a recycling facility?

A: Key benefits include reduced manual labor, increased throughput, minimized storage requirements, and enhanced safety. The automated features and robust build provide long-term cost savings for businesses.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Hydraulic Baling Press' category

Send Inquiry

Send Inquiry Send SMS

Send SMS